There are 2 DIP automatic peak lines, 2 post-welding lines, and 4 test lines; especially good at high-precision and high-complexity boards.

| DIP production line | 2 pieces |

| DIP capacity | 20000 sets PCBA/day |

| Post wire | 2 pieces |

| Post welding capacity | 10000 sets of PCBA/day |

| Test line | 4 pieces |

| Test capacity | 10000 sets of PCBA/day |

SMT patch, assembly and processing one -stop electronic manufacturing service provider, undertake full support services such as patch, plug -in, post -welding, testing, aging, assembly, packaging, packaging, packaging, packaging, packaging, etc.

Dongguan Junze Electronics Co., Ltd. was established in 2021 with a registered capital of 1 million. It is located on the third floor of Building 1, Zhonggaocheng Innovation Industrial Park, No. 10, Xinju Road, Shangjiao Village, Chang'an Town, Dongguan City. With a production area of 3200 m², it is a technical enterprise engaged in the one-stop manufacturing of PCBA-OEM, ODM placement and DIP plug-in semi-finished/finished products assembly testing aging packaging.

Adhering to the concept of "quality first, focus on innovation; quick response, professional service", based on the continuous improvement of ISO9001, the introduction of the most advanced production equipment and excellent technical management personnel, is committed to providing customers with satisfactory products and services.

The main services are: Electronic product ODM/OEM (SMT/AI/DIP, Assembly/FCT)

The company currently has 4 fully automatic SMT lines, 2 automatic peak DIP lines, 2 finished product assembly and testing lines, and an engineering professional technical/management team with more than 15 years of experience.

The pre-production engineering of Cam/MI is carefully optimized, and the PCB soldering yield rate of our manufacturing is industry-leading, reaching 99.8%

100 professional and technical talents of PCB experience more than 10 years have rich experience in various industry standards and technological quality requirements

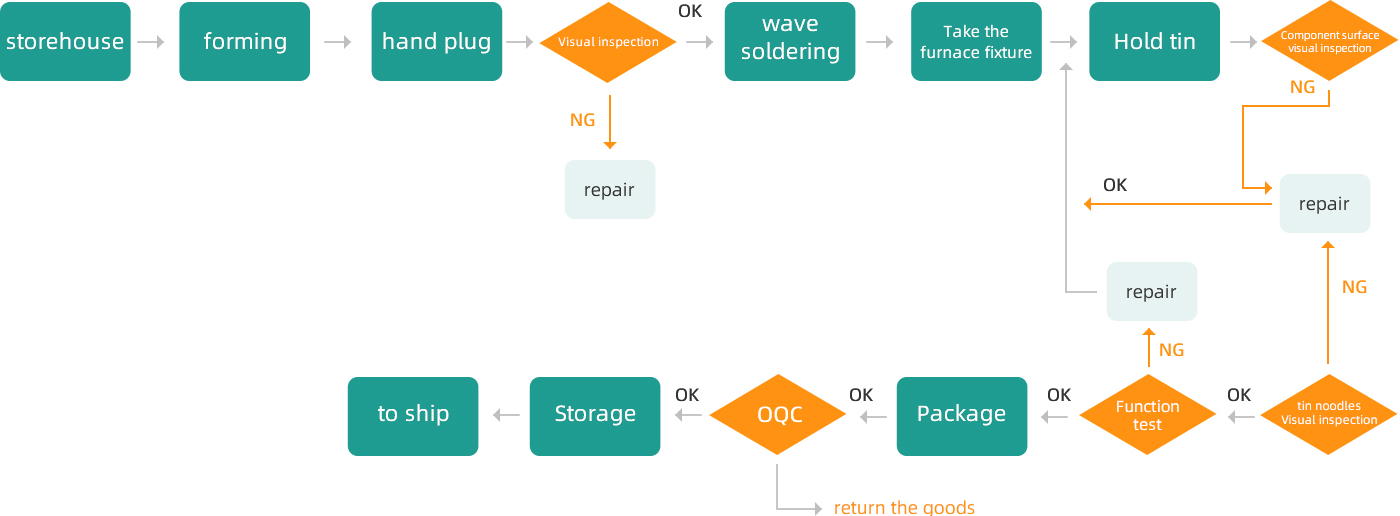

The production line is equipped with high-end equipment, high-precision and high-yield processing. *Carry out quality inspection and control in each processing link to prevent defective products from flowing into the next link. *Set up a number of quality personnel for random inspection throughout the process.

1. Adhesive cardboard: test whether the SMT mounting position is correct, greatly reduce the time of SMT trial production and the waste of components, and effectively ensure the quality of SMT

2. Intelligent first article detector: detect wrong materials, missing parts, polarity, direction, silk screen, etc., mainly used in manual inspection of first article detection, with higher accuracy and 50%+ speed increase

3.SP|-Automatic 3D solder paste thickness gauge: detect various solder paste printing quality problems such as missing printing, less tin, more tin, tin connection, deviation, poor shape, board surface pollution, etc.

4, Aol: Detect various problems after placement: short circuit, material leakage, polarity, displacement, wrong parts

5, Xray: Open circuit and short circuit detection for BGA, QFN and other devices

Many years of industry experience, rich SMT patch, DIP plug -in, assembly processing manufacturing production experience, professional design, research and development of production quality management team